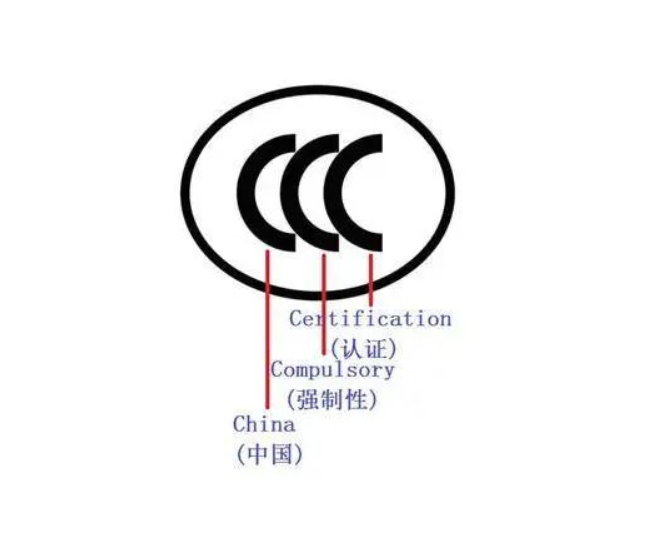

In the TWS headphone industry chain, the battery is a core component, and its compliance directly affects the market access and brand reputation of the product. According to data from the State Administration for Market Regulation, consumer complaints caused by battery problems in 2023 accounted for 23.6%, most of which involved lack of certification. For manufacturers, 3C certification is not only a legal entry threshold, but also a key line of defense to build market competitiveness.

The special requirements of 3C certification for TWS batteries are reflected in multiple dimensions. In the safety test, it is necessary to pass 16 rigorous experiments such as overcharge/overdischarge and high temperature shock, among which the thermal runaway protection index requires that the battery does not fire or explode within 30 minutes under abnormal conditions. In terms of electromagnetic compatibility, it is required that the radiation value of the battery pack does not exceed 30dBμV/m when working in the Bluetooth band. It is worth noting that the 2023 version of the new regulation adds a wireless charging compatibility test, requiring that the temperature rise of the battery does not exceed 42 ° C when working under the Qi standard.

In the process of certification implementation, manufacturers often face three major challenges: First, the battery supplier qualification audit, it is necessary to check whether the supplier has the system certification required by the Implementation Rules for Compulsory Certification of Lithium-ion Battery Products; The second is technical document preparation, need to provide a complete BOM list, circuit topology diagram and FMEA analysis report; The third is the sample consistency control, the structural process deviation between the mass production product and the sample shall not exceed 5%. It is recommended that enterprises establish a whole-process traceability system from raw material procurement to finished product testing, and regularly conduct self-inspection of conformity.

For the pain points of long certification cycle (usually 45-60 working days), it is recommended to adopt the strategy of "pre-certification + parallel testing". Getting involved in certification consulting at the research and development stage and using third-party laboratories for pre-testing can shorten the certification cycle by 30%. By establishing an internal compliance laboratory, a certain head ODM manufacturer increased the certification pass rate to 98%, saving certification costs of more than 2 million yuan annually. If you need certification, please contact ZRLK!